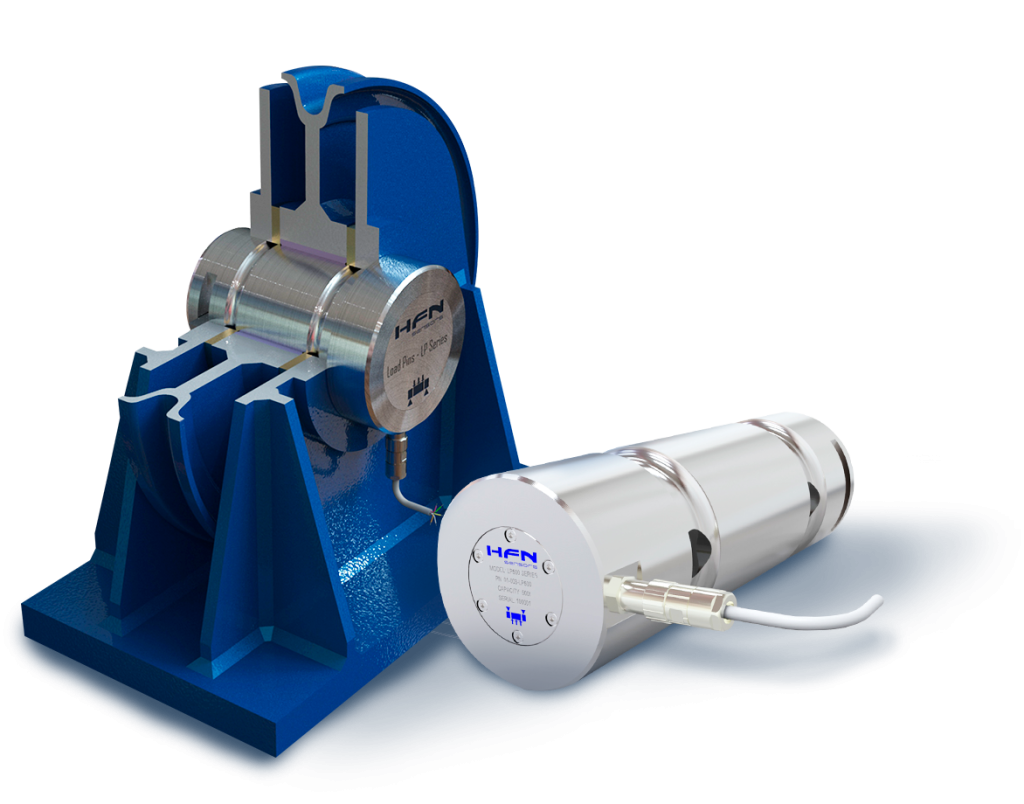

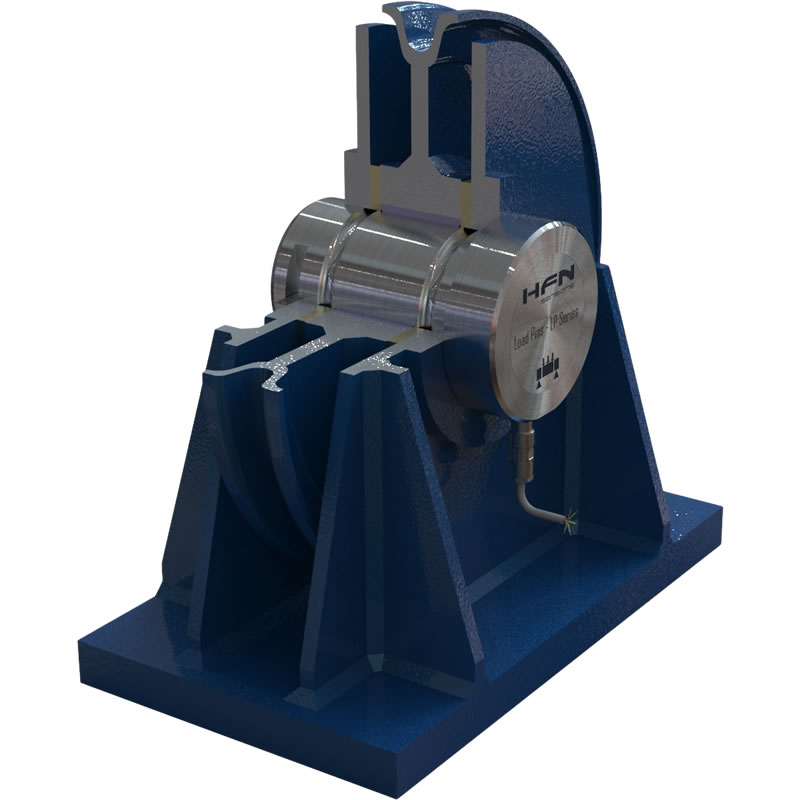

Load Pin Load Cell – LP Series

The Ultimate Solution for Load Monitoring with the Load Pin LP Series

HFN Sensors is a market leader in sensors and load cells, providing innovative and customized solutions for industrial, offshore, and lifting applications.